Surface Acoustic Wave Substrates

Starting in 1994, the BPO team was the first group to offer non-commodity crystal quartz and lithium niobate SAW substrates. This service is still available today.

Most custom SAW substrates are square or rectangular with customer specified back surface roughness. Orientations are frequently unique and tightly controlled. Our development of the chemical SAW polish for quartz has led to many other applications of this finishing technique. We are size limited only by the availability of your chosen material and orientation.

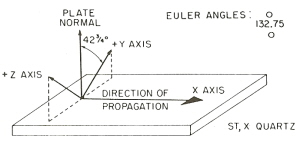

Boston Piezo-Optics has been manufacturing surface acoustic wave substrates for over thirty years. SAW devices continue to be of interest because of their superior functional characteristics in delay lines, filters, and other UHF, VHF and microwave devices. We possess considerable experience in the manufacture of ST-cut, AT-cut, and any single or doubly rotated Y-cut crystal quartz wafers or substrates. We can also provide Lithium niobate substrates in rotations such as Y-Z or 128° rotated Y-cut.

All of our SAW substrates are fabricated from high quality single crystal quartz or lithium niobate. All raw material is X-ray oriented and optically inspected to ensure freedom from mechanical flaws and electrical and optical twinning.

Surface acoustic wave plates are available as finished substrates or as blanks. The finished substrates have a special chemical SAW polish on one surface, with a 3 micron fine lapped finish on the other major surface. We can also provide substrates with a rougher finish on the backside to eliminate any unwanted interference that may result from mode conversion.

We specialize in making substrates to non-standard designs. We are limited only by the dimensions of the available raw material.

Surface Acoustic Wave Substrate Finishing

The surface acoustic wave finishing technique combines mechanical grinding with the discreet application of chemical polishing technology. It produces a uniformly smooth surface with a minimum of surface dislocation and sub-surface damage.

The polished surface of our surface wave plates is typically flat to 2 waves per inch. Surface is free of visible processing defects under 50X Nomarski examination.

General Specifications

| Material | Standard Orientations | Orientation Tolerances | Dimensional Tolerances |

|---|---|---|---|

| Single-crystal Quartz | ST, AT, AC, Y X Length |

+/- 15' +/- 30' |

Length: +/- 0.005" Width: +/- 0.002" Thickness: +/- 0.002" (typical) |

| Lithium Niobate | Y-Z Z Length |

+/- 15' +/- 30' |

Length: +/- 0.005" Width: +/- 0.002" Thickness: +/- 0.002" (typical) |

Other orientations and dimensional tolerances available upon request.

Material Characteristics

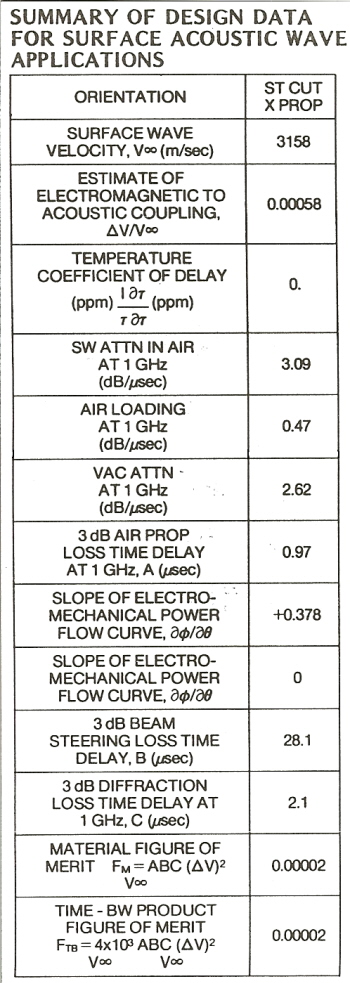

| Orientation | Velocity (m/sec) | D v/v | Coupling Constant | Slope of Power Flow Angle | Temp. Coefficient of Delay (ppm°C) | Applications |

|---|---|---|---|---|---|---|

| ST-X Quartz | 3158 | 0.00058 | 0.045 | +0.378 | 0 | Filters, Delay Lines, Wide Band Filters |

| Y-Z Lithium Niobate | 3488 | 0.0241 | 0.045 | 0 | +94 | Filters, Delay Lines, Wide Band Filters |