Piezoceramic Tubes

Boston Piezo-Optics manufactures piezoceramic tubes from select, void free, high quality, homogeneous PZT billet material. Our exclusive machining process insures meeting and exceeding the most stringent mechanical and acoustic specifications.

Electrode options are electroless nickel, or electroless nickel plus electroless gold. These thin film electrodes add durability, solderability, low mass and excellent conductivity.

Custom Electrode Options

- Single or double wrap tab pattern

- OD circumferential bands

- Axial segmenting on OD (Angular spacing and width of segments can be specified)

- Custom electrode removal on OD

- Leadwire attachment

- Electrode removal of OD and ID at tube ends

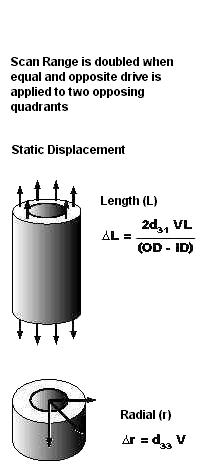

Static Displacement Calculator

Need to know how much displacement can be achieved by your tube configuration? Try our static displacement calculator to see the theoretical motion.

Static Displacement CalculatorThe field of fiber-optics research has benefited from the uniform radial expansion of the tube OD, to stretch optical fibers for enhanced signal tuning. Tube sizes can be custom fabricated to maximize radial expansion for this fiber optic application.

Piezoceramic tubes are recommended for applications where acoustic directivity, simplicity, or size constraints are the primary design concerns. Boston Piezo-Optics manufactures high precision tube crystals from lead zirconate titanate compositions.

Tube applications range from the latest scientific developments of Scanning Tunneling Microscopy (STM) and Atomic Force Microscopy (AFM) to medical diagnostics and therapeutics. Other applications include micro positioners and vibration detection, ultrasonic pumps and liquid atomizers, phonograph pickups and hydrophones. Tubes are routinely supplied as transverse rings or longitudinal or radial mode hollow cylinders.

Boston Piezo-Optics's Sonic Mill capabilities are unmatched for the fabrication of piezoceramic tubes. Sonic Milling is much gentler to the walls of the tube which minimizes surface imperfections that could eventually result in cracks or breakage. Sonic milling is ideal for the fabrication of tubes with thinner walls as well as for the fabrication of very small tubes for medical applications. Piezoceramic tubes can be manufactured to internal diameters of less than 1.0 mm and as large as 20 mm using our Sonic mill equipment and expertise.

Electrode choices are electroless nickel or electroless nickel plus electroless gold. Various electrode patterns are available depending on tube size and application.

General Specifications

| Material | Mode of Vibration | Diameter (typical) | Wall Thickness (typical) | Length (typical) | Electrodes |

|---|---|---|---|---|---|

|

Lead Zirconate Titanate: PZT-4 PZT-5A PZT-5H PZT-8 |

Radial, Compressional, Shear |

0.060" 0.100" 0.125" 0.250" 0.375" |

0.010" 0.012" 0.015" 0.020" 0.030" |

0.125" to 3.000" | Electrode choices are electroless nickel or electroless nickel plus electroless gold. |

This table is intended only as a general guide - all tubes are custom manufactured to your specifications.

Suggested Reading

- "Introduction to Scanning Tunneling Microscopy" - C. Julian Chen, Oxford University Press, 1993.

- Applied Physics Letters, Jan. 6, 1992, pp. 132-134. "Electromechanical Deflections of Piezoelectric Tubes with Quartered Electrodes" - C. Julian Chen

- Review of Scientific Instruments, Aug. 1986, pp. 1688-1689. "Single-Tube Three Dimensional Scanner for Scanning Tunneling Microscopy" - G. Binning and D.P.E. Smith